Creating a 3d Printing Revolution.

Get ready to dive into a world of endless creativity and unmatched productivity with Formlabs 3D printers! Having a Formlabs printer is more than just owning a piece of technology; it’s an extraordinary experience that changes the way you create and manufacture things. We, at Layers 3D, recognize the crucial role these printers play in boosting efficiency, cutting costs, and inspiring innovation. Opt for us as your 3D printing collaborator to tap into limitless creative possibilities and effortlessly bring your ideas to life.

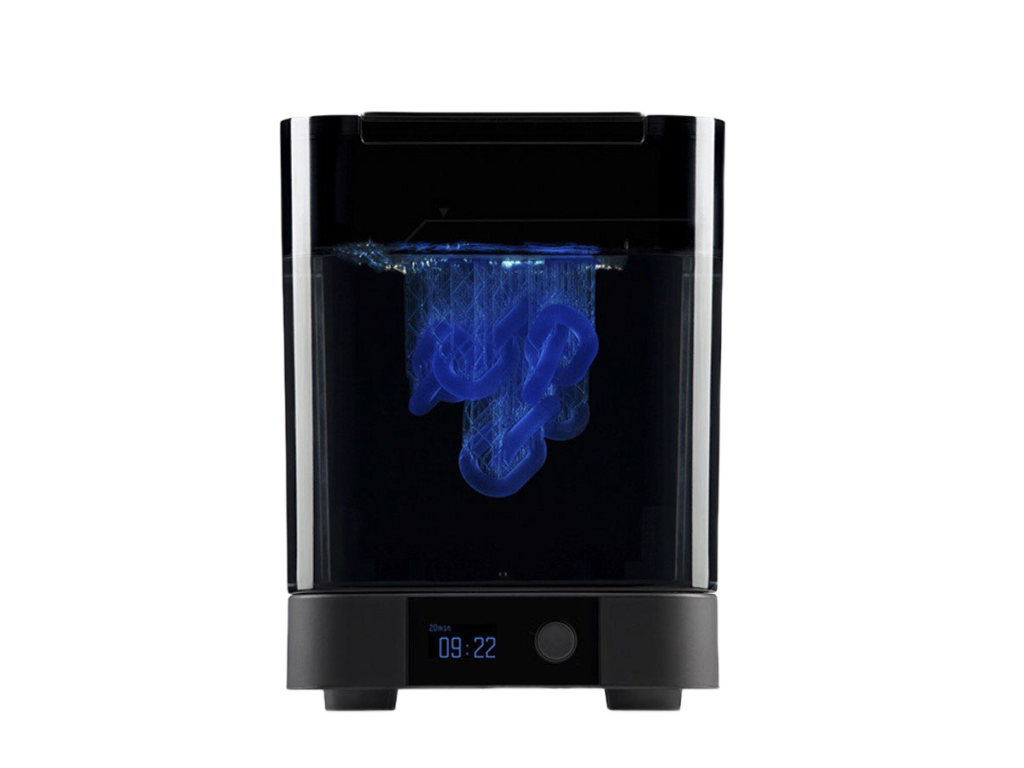

wash

The Form Wash aSutomates the print washing process and provides consistent, thorough, no mess cleaning for parts printed on the Form 2, Form 3, and Form 3B.

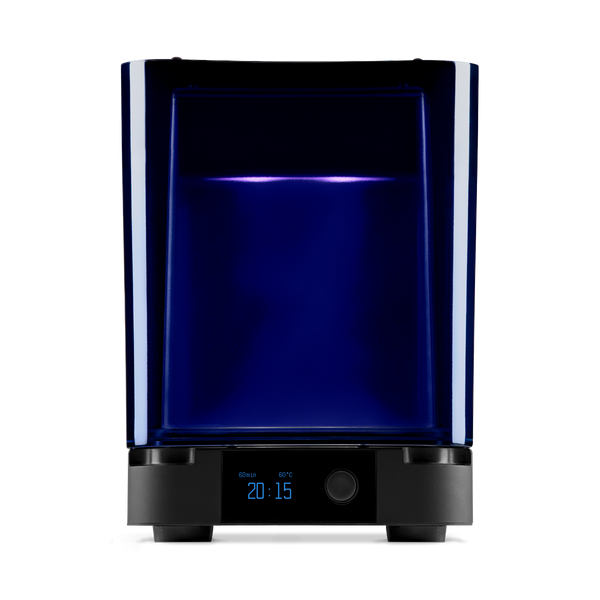

Cure

The Form Cure precisely combines temperature and 405 nanometer light using 13 multi-directional LEDS to post-cure parts for peak performance.

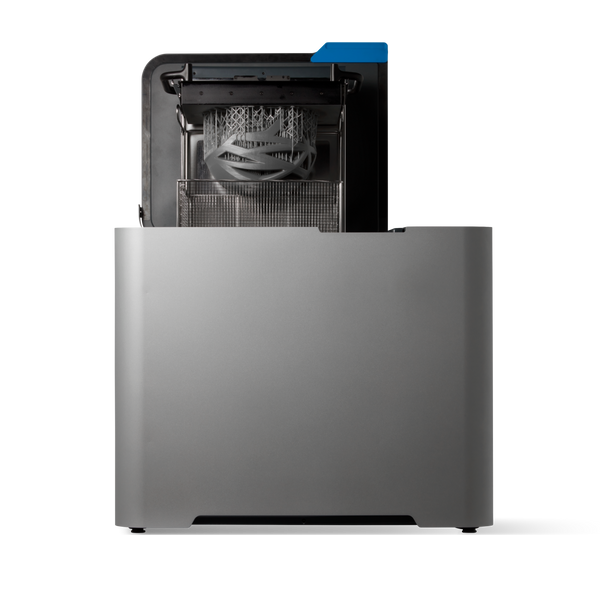

wash-L

Automated large-capacity cleaning facility for use with Form 3L and Form 3BL 3D printers.

Formlabs Form Wash L provides an automated washing process for your post-print SLA parts. Parts can be kept on the build platform, transferring straight from the printer to Form Wash L. Once washing completes, the Form Wash L automatically opens to lift parts out of wash solution.

Form Wash L can be used for large parts, with maximum part size of 33.5 x 20 x 30 cm, and has a bucket capacity of 37.9 litres. The embedded solvent monitor helps maintain peak cleaning performance by displaying a notification when it’s time to replace the wash solvent.

Pair the Form Wash L with the Form Cure L for the full streamlined post SLA print process

cure-L

Professional large-format curing station for use with Form 3L and Form 3BL 3D printers.

Formlabs Form Cure L provides a reliable, professional post-curing solution for large SLA 3D printed parts, precisely controlling temperature and light to cure parts to their optimal performance properties. Choose from default time and temperature settings for standard resins, or select specific settings via the on-board controls.

fuse sift

The Formlabs Fuse Sift is a safe, efficient powder recovery system for the Fuse 1 or Fuse 1+ SLS 3D printers.

This all-in-one station combines part extraction, powder recovery, storage, and mixing in a single free-standing device. Fuse Sift enables the ability to produce functional parts at an industry leading 30% powder refresh rate, with unlimited cycles. This means you can print with up to 70% recycled powder.

Fuse Sift will dispense and mix used and new powder automatically so you can reduce waste and control your powder supply

finishing tools

Professional large-format curing station for use with Form 3L and Form 3BL 3D printers.

Formlabs Form Cure L provides a reliable, professional post-curing solution for large SLA 3D printed parts, precisely controlling temperature and light to cure parts to their optimal performance properties. Choose from default time and temperature settings for standard resins, or select specific settings via the on-board controls.