Creating a 3d Printing Revolution.

Get ready to dive into a world of endless creativity and unmatched productivity with Formlabs 3D printers! Having a Formlabs printer is more than just owning a piece of technology; it’s an extraordinary experience that changes the way you create and manufacture things. We, at Layers 3D, recognize the crucial role these printers play in boosting efficiency, cutting costs, and inspiring innovation. Opt for us as your 3D printing collaborator to tap into limitless creative possibilities and effortlessly bring your ideas to life.

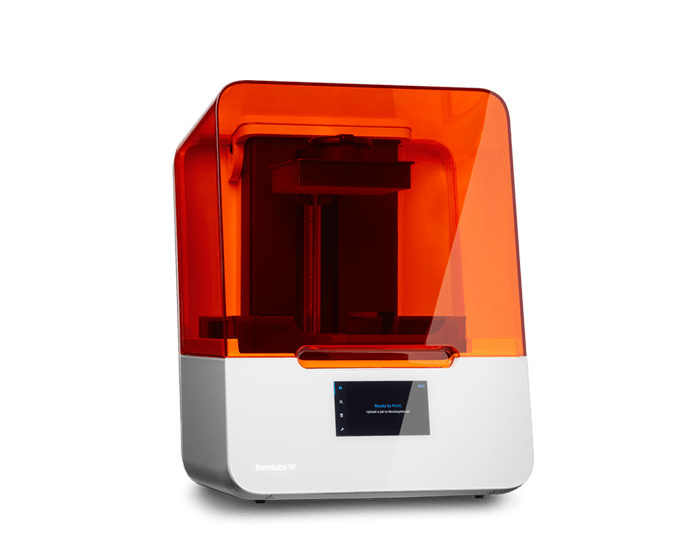

Form 3 +

Each Form 3+ Low Force Stereolithography (LFS)™ 3D printer package includes a one-year warranty and the essential tools required to start printing.

Produce functional, high-quality prototypes and end-use parts in record time with the Form 3+, an affordable, industrial-quality 3D printer that consistently delivers. The Form 3+ offers rapid print speeds, industry-leading accuracy and reliability, and a wide range of materials.

The Form 3+ is powered by Low Force Stereolithography which consistently delivers presentation ready parts with unbelievable surface finish. After printing, detach supports in seconds with our enhanced Light Touch Support structures that save post-processing time.

The Form 3+ is simple to set up and maintain. Use the Form 3+ for both prototyping and production and easily add more capacity as demand grows.

Form 3B+

Each Form 3B+ Low Force Stereolithography (LFS)™ 3D printer package includes a one-year warranty and the essential tools required to start printing.

Rapidly print patient-specific parts at the point of care and bring innovative R&D and commercial production in-house with the Form 3B+, an advanced 3D printer for healthcare professionals and medical device engineers. The Form 3B+ is compatible with our SLA materials library, including biocompatible, sterilizable materials manufactured in our FDA-registered, ISO 13485-certified facility.

The Form 3B+ is simple to set up and maintain; no specialized training is required. From time-sensitive point-of-care printing to groundbreaking medical device development, work faster and have complete control with a versatile, accessible, and scalable 3D printer on-site.

Form 3L

The Form 3L is an affordable large-format 3D printer designed for professionals to provide fast turnaround of industrial-quality parts, printed using the advanced Low Force Stereolithography (LFS) process.

Take control of large-format prototyping and bring your biggest ideas to life with the Form 3L, a cost-effective 3D printer that doesn’t compromise on the details.

Form 3BL

3D print adult patient-specific anatomy at 1:1 scale or large medical devices in one build with the Form 3BL, a large-format 3D printer developed for medical professionals. This 3D printer is compatible with the majority of our SLA materials library, including biocompatible, sterilizable materials.

Form Auto

Form Auto from Formlabs is an automation ecosystem for continuous high-throughput SLA 3D printing.

Form Auto is a hardware extension for the Form 3+ and Form 3B+ series 3D printers that automatically removes finished parts from Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 3D printing with no printer downtime.

The Form Auto is ideal for those needing to produce multiple part batches with minimal downtime.

Use Form Auto as part of a fuller automation ecosystem, eliminating idle printer time with additional solutions:

Fuse serires

As a premium industrial SLS solution, the Fuse 1+ 30W is capable of faster part production and higher-performance materials.

Designed for maximum output and minimum waste, Fuse 1+ 30W is compact SLS 3D printer that unlocks faster print speeds and a full range of materials to deliver truly rapid prototyping and production in-house.

Building on effective powder containment, the Fuse 1+ 30W is equipped with a powerful 30W laser enabling same-day delivery of prototypes and end-use parts. Active powder handling unlocks the use of new materials such as Nylon 11 CF (carbon fibre) and TPU 90A (flexible).

An optional nitrogen purge print system allows for further increased part performance, consistency and improved powder refresh rates.

The Fuse has a build volume of 165mm x 165mm x 300mm and, combined with the Formlabs Fuse Sift, can produce fully-functional parts at an industry leading 30% powder refresh rate with unlimited cycles.